Engineering

Company Overview

The development of today’s world delves mainly on its mechanical power. Due to the transition into the Global economy, the condition of the industry today is such that competition among manufacturers, importers and exporters to maintain market share, continue to drive down the price of maintaining shop floor equipment and in turn reduce the cost of producing the products. For many years, companies have enjoyed a healthy profit margin on the products they produced and competed simply on price and quality, rather than using creative ways of reducing cost for their internal process to enhance customer value. This is the area that MIDAS excels in. Through many years of hands-on experience in the manufacturing industry and excelling in utilizing technological advances, Midas management team has a proven track record in setting industry standards.

The state-of-the-art technology used in our production units in Chennai gives that magic touch of extra richness and elegance. All this is complemented by a professionally managed approach of timely deliveries, competitive prices with quality, matching world standards and rock-like reliability of the company’s resources. We achieve this through our experienced and trained manpower and sales network around the country established for superior customer service.

History

In the year 1986, a company was found in the name of “Fabri-com Industries”. In 1996, MIDAS – “The Golden Touch” bought Fabri-com Industries to form Midas Fabri-com Technologies Private Limited. Ours is a private limited concern, that owns and operates several industrial units at Chennai in India. We support our customers in various fields like Design, Research & Development, Manufacturing, Consulting, Marketing etc. Commercial operations have been successful for the last fifteen years enjoying total customer satisfaction.

Description of Business

All operations are conducted from its headquarters located in Chennai, India where the company occupies an aggregate of over 20,000 square feet and employs over 60 full time permanent employees. Company operations are dedicated to Engineering Development, Prototyping, Fabrication, Casting, Molding and Assembly. Within the private sector, we provide manufacturing development and production of commercial instrumentation or systems, sub-assemblies, and components. On government-related contracts, we perform small to medium-scale research and development, rapid prototyping, manufacturing development, and production for Aerospace, Defense, Railways, Energy, Environmental, and Telecommunications customers.

Midas builds application specific equipment, machinery and components. Beyond providing standard job shop machining, welding, fabrication and electro-mechanical assembly services, Midas is a designer, integrator and manufacturer of custom automated industrial and commercial process equipment and machinery. We offer customized cost effective solutions to your product, process and manufacturing challenges.

Why Midas

With our extensive special machining capabilities and sophisticated machine tools, Midas can supply virtually any standard or special component, or perform any machining job, no matter how complex. Our many years of technical know-how have provided us with a degree of efficiency unparalleled in the industry. Midas has the unique capability of producing virtually any special task our customers may need.

Midas offers full engineering and design service to complement our in-house manufacturing capabilities. From conceptual development of a single component part through detail drawings of complete automated systems, we can provide application specific manufactured solutions for your process challenges.

We provide quick response to our diverse customers’ needs. Our emphasis on the importance of strong relationships with our supplier base enables us to continually meet tight delivery schedules. By combining the responsive procurement of materials, components and support services with our in-house capabilities, we offer a total quality solution from a single source for all your manufacturing requirements. To top it all, we have our representatives in Midwest region of United States providing the service level you are accustomed to and at the same time realize cost benefits for your company.

“Our Mission is focused to ensure Customers Satisfaction by Delivering Quality Products Just In Time (JIT) meeting the required Specifications by strictly adhering to the Quality Control Standards keeping the Cost Competitive.”

Those who place their trust in us benefit from the following:

- Midas is committed to provide Quality Products and Service with an emphasis on understanding the stated and implied needs of the customers and also ensuring on-time delivery.

- New product range along with an improved and Lean process flow.

- One-stop solution to all the opportunities in the manufacturing industry.

- People are the greatest assets of Midas. The company is committed to investing in each employee, taking them through the technological evolution, training and upgrading them to be the best that they can perform.

- Quality end products.

- Real-time response to customer needs.

- System – The Company takes great effort and pride to develop each part of the process and combines software (people) and hardware (technology and equipment) with great effect. The end result is a quality-driven process that brings each project from concept to reality.

- Technology – Midas is a firm believer in exploiting advanced technologies to produce quality tools. 3D-solid CAD/CAM applications, state-of-the-art high speed CNC and EDM machines help bring the most economic product with high accuracy.

- Understanding customer needs.

- Value – With years of experience in the manufacturing business, Midas understands the value of clients’ business and is well focused to undertake each project – no matter how demanding or complex.

- Web based interaction with the affiliation of “DrMachines.com” provide complete online solutions to all our clients.

Products & Services

Midas specializes in Hydraulic Presses for applications like Deep Drawing, Cold Forging, Compression Molding, Rubber Molding, Diamond Tools & Grinding Wheel, Powder Compacting, Assembling & Forming for special purposes, Broaching Machine, Bailing Press for paper, steel scrap, etc. These presses can be built in Closed Frame, C – Frame, Pillar Type constructions with capacity ranging between 5T to 300 Tones. We also specialize in Hydraulic Cylinders in Tie-Rod, Welded, and Bolted constructions.

Midas designs and develops Moulds like Plastic Moulds, Rubber Moulds, Injection Moulds, Compression Moulds, Vacuum Moulds, Round Moulds and many more. We also provide services to large-scale production of the products according to the above moulds.

Midas is one of the pioneers in kitchen equipment industry. The activities in this field presently are

- Design, fabrication supply, erection, testing & commissioning of exhaust & fresh air system.

- Fabrication of stainless steel products as per technical specification (Distillery units, Dairy units, Pharmaceutical units, Chemical industries etc.) of our customers.

Super Drill EDM: Midas also serves extensively in the field of minute hole drilling applications. Diameter 0.3 to 3.0mm holes up to 150mm long holes on the materials like Carbide, HSS, Titanium alloys; Stainless Steel etc. can be drilled.

To produce the best machines, & products, Precision gauges have become necessity. Midas specializes with the production of special gauges and standard gauges like Standard Plug Gauges, Fixed Snap Gauges, Gauge Pin Sets, Settling Masters (ring & plug), Flush Pin Depth Gauges, Concentricity Gauges etc.

Midas deals with Ejector Pins (DIN 1530) & Piercing Punches (DIN 9861/IS 4296). Ejector Pins are made from superior quality hot die steel and high carbon & high chromium steel according to customer requirement. Piercing Punches are made from superior quality imported high-speed steel (6-5-2) and also from WPS steel. However, high-speed steel (6-5-2) is recommended for punches of less than 6mm Diameter. Ejector Pins and Piercing Punches have head hardness and shank hardness specifications as per DIN standard recommendations. They are center-less ground and lapped to get a good finish. This makes Midas to deliver the best quality products.

Partial List of Projects completed

Press Tools – Snail Assembly

Supplied to Heavy Vehicles Factory

Press tools are used for production of sheet metal components as per specification. Some of the examples are blanking tools, pressing tools, forming tools, deep drawing tools, bending tools etc. Snail assembly is a blanking tool that is used for blanking the components of cover with thickness of 2mm MS plate in a mass production.

This tool consists of top and bottom plate with the support of pillar set. The ‘Punch’ is in the top plate and the ‘Die’ in the bottom. The material used for Punch and Die is high Carbon high Chromium with good shear properties. Most of the mechanical operations such as shaping, drilling, boring, wire-cutting etc along with proper heat treatment are involved to form the final tooling. To be economically competitive, this tool was machined in various joints and were screwed to the bottom plate as pillar set instead of doing all as one piece. These tools are used extensively in power and hydraulic presses.

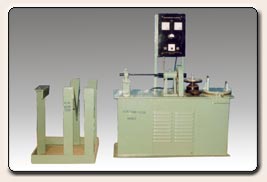

Testing Equipments – Taco-Generator Calibration Equipment

Supplied to Heavy Vehicles Factory

Testing equipments are needed for the calibration of just about any engineering product/research. This Taco-Generator works on DC variable speed drive with thermostat control unit. This equipment consists of voltmeter, ammeter, speedometer, stands along with the panel board. In the panel board, a display unit is provided to check the RPM on speedometer with the voltage produced by Taco-Generator with respect to the load. On this system, we can see a speed ranging 0 to 4000rpm and voltage ranging 0 to 24v. These testing devices are specially used for testing and calibrating the tacometer and generator in the heavy vehicles.

Precision Components – Hylam Sealing Ring

Supplied to Engine Factory

These machined components have accuracy with very low or no tolerance limit that are used in critical engineering projects. Hylam sealing ring is a component that is used in crankshaft end seal for T-72 Tank V46-6 Engine to avoid leakage of oil in the engine. Sealing rings are made from Fabric Base laminated tube (Hylam) to TF2211 OD 148mm X ID 125mm. The springs used in sealing rings are made from grade 3 to IS 4454 with a diameter of 0.5mm wire. We have various tests performed on the raw material, as per IS 2036 type to check the tensile strength, impact strength, strength, water absorption, compression strength, electrical strength etc.

To manufacture Hylam sealing ring, first the ring is parted to the required size along with the facing of surface ‘A’ and ‘B’. The face out of surface ‘B’ is maintained at no more than 0.05mm. The surface is milled and turned along with the outer groove. The ring is bored to the required size. The ring is tipped with the mandrel in the oil at 50°C (OIL MT -16N) and heated to 125 – 135°C for 14 hours. It is then unloaded after cooling down to 50°c along with the mandrel. Operations such as lapping, blue checking, boring are performed with the spring. Midas quality team as well as Special Forces from army checks all the dimensions for complete accuracy as per specifications.

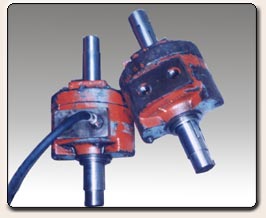

Assembly Components – Actuator

Supplied to Port Trust of India

Assembly of three or more precision components is known as assembly components. Some of the examples are pumps, valves, actuators, suction pipes, oil pipes, container lifting cranes etc. Actuators are mainly applicable for work holding devices, work piece movement (horizontal & vertical) at power station, machine shop, and material handling systems.

Housing is manufactured in molded cast iron. The shaft and shaft arm is manufactured in EN19. An oil seal for packing is manufactured in Teflon, Terrylin and Rubber. Pin is obtained in EN19 material. Midas developed the design and manufactured actuators to successfully launch major projects for our clients. Various mechanical along with electrical operations are involved in the manufacture of an actuator. Along with design & supply, we also provide long-term service/reconditioning of the defective actuator.

Fabrication – Air Damper

Supplied to Vanjax Sales Private Limited

Midas specializes in the design, preparation of shop drawings, manufacture, inspection, testing of air dampers. The construction of the damper should be suitable for operation at required temperature. This is provided by differential thermal expansion chamber. The frame is made of carbon steel. Damper blade and shaft are made of stainless steel. Seals are made from Enconel 625. Insulation is provided with ceramic fiber blanket.

The principal material for construction should be suitable with respect to fluid and temperature. The ends are suitable for bolted connection. This mates the flanges on both sides of the damper. After the reactor shuts down, the nuclear heat generated in the core due to decay of radioactive fission products is removed through the normal heat transport path consisting primary & secondary sodium and water steam circuit. In the absence of normal heat transport, safety grade decay heat removal circuit is used.

Hydraulic Fabrication – Floor Crane

Supplied to Vanjax Limited

Midas has successfully been in production of floor cranes that are used in the automobile industry. Floor cranes are used to lift the engines up to 1ton capacity in the car. It is compact, lightweight, easy to carry anywhere along with the wheels. It is made out of steel rectangular tube. Its major construction is fabrication with the help of TIG welding. Hydraulic cylinder and hand pump are attached to this construction to lift an engine easily. Attempts with similar concepts are being made to lift the entire car itself.

Private SectorGreaves Limited: Heavy Engine Unit

- Ashok Leyland: Truck Manufacturers

- Hindustan Aeronautics Limited

- Bharat Electronics Limited

- Amalgamation Valeo Clutch Limited

- Larsen & Turbo Limited

- Greaves Limited

- Brakes India Limited

- Pressform Industries

- Devendra Exports

- Vanjax Sales Private Limited

- Ford India Limited

- HCL Limited

- Lucas-TVS Limited

- Sundaram Industries Limited

- Valeo Friction Materials India Limited

- Whirlpool India Limited

- TVS Suzuki Limited

- Hyundai Motors India Limited

- Hindustan Motors Limited

Government Sector

- Heavy Vehicle

- Engine Factory: DOD

- Small Arms Factory

- Ennore Thermal Power Station

- Chennai Port Trust

- C.V.R.D.E.

- Ordnance Factory

- Gun & Shell Factory

- Field Gun Factory

- Small Arms Factory

Partial List of Equipment

Shearing Machine

Molding Machine Germany

Hydraulic Presses

CNC Vertical Machining Center – Supermax (USA)

Many more equipment with well equipped standard room with all types of measuring devices along with optical profile projector to fulfill all the requirements needed in this Industry.